Our Products

BCS specializes in stainles steel, aluminum and fiberglass parts for industrial applications

Example products could be:

Wind power:

- Glue flanges and Spinner rings for blades

- Hatches and covers

- Nacelle parts and more…

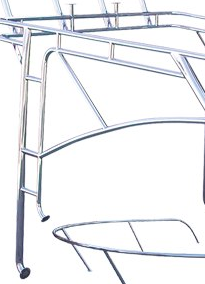

Marine:

- Hulls and decks

- Innerliners, hatches & covers

- Pulpits, ladders, steerings wheels

- Tanks

- Deck fittings and more…

Interior/Projects:

- Hand rails, columns

- Kick plates

- Custom made fittings

- Furniture parts

- Doors and windows

- Decorative parts and more…

Fibre Glass

BCS specializes in less complex, labour intensive fiberglass parts for industrial applications.

The manufacturing process is mainly hand layup of polyester and glass fibre mats in single sided moulds. Solid laminates or with sandwich core. Choice of materials, laminate plan and specs according to customer specifications.

Our manufacturers have experience in large structures up to 1500kg of laminate (such as yacht hulls), and pay special attention to surface quality and laminate structure.

Moulds can be made from new plug, or from customer supplied plug/part.

Our manufacturers are located in western Poland and have own transportation vehicles for easy and safe delivery to your door.

Stainless Steel / Alu

BCS specializes in alu and acid proof / stainless steel parts for industrial and outdoor applications according to customer order.

Most of our products are made in AISI 316L, AISI 304 or aluminum, but other materials are available upon request.

Our manufacturers posses modern machines and offer high quality products with superb surface finish based on the following technologies:

Our manufacturers use AutoCAD and Solidworks (for 3D). Drawings are accepted in DWG/DXF or even PDF formats. In some cases, STP-files can be used directly.

Naturally, we can arrange the transportation of the goods to your door..